Igama elithi hemming linemvelaphi yalo ekwenziweni kwelaphu apho umphetho welaphu usongiwe ubuyele kuwo kwaye emva koko uthungwe uvalwe.Kwi sheet metal hemming kuthetha ukusonga intsimbi ngasemva kuyo.Xa usebenza ngeBrake Press hems zihlala ziyilwa kwinkqubo yamanyathelo amabini:

Yenza i-bend nge-Acute Angle Tooling kwintsimbi, i-30 ° ikhethwa kodwa i-45 ° iya kusebenza kwezinye iimeko.

Beka i-bend ebukhali phantsi kwe-bar flattening kwaye usebenzise uxinzelelo olwaneleyo ukugqiba ukuvala ukugoba.

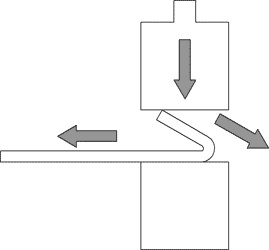

Isinyathelo sokuqala senziwe ngendlela efanayo nakweyiphi na i-angle eguquguqukayo eqhelekileyo.Inqanaba lesibini lenkqubo ye-hemming lifuna ulwazi olongezelelweyo malunga nendlela kwicala lomqhubi we-Brake Press kunye nomyili wesixhobo kuba i-engile ye-sheet metal, i-bar flattening ifuna ukutyibilika phantsi kwaye kude ne-sheet metal.Ukongeza isiqwenga somsebenzi sifuna ukutyibilika siphume phakathi kwemivalo.La mandla mabini aziwa ngokuba yi-thrust forces.

UMzobo we-Trust Forces ukusuka kwi-Hemming Sheet Metal

Oku kufuna ukuba idiyizi ecaba ilungiselelwe ukumelana nokutyhala kwaye ihlale ithe tyaba.Ukongeza, ifuna ukuba umqhubi abeke amandla angaphambili ngokuchasene nephepha lentsimbi ukuyithintela ukuba ingatyibiliki ngaphandle kwedayiti.La mandla agqame kakhulu kwiziqwenga zokusebenza ezityebileyo ezineeflentshi ezimfutshane.Sinale miba engqondweni makhe sihlole ezintathu zeendlela eziqhelekileyo zokuseta i-hemming kunye nezixhobo ezifumanekayo kwiziqhoboshi zokucofa.

Ukuseta iSixhobo esiNinzi, iSixhobo esiAcute kunye nokuFlatyiswa kweDie

Eyona ndlela ilula yokuseta i-hemming idibanisa ukuseta ezimbini ezahlukeneyo.Eyokuqala i-acute setup, apho i-30 ° bend idalwe ngokusebenzisa izixhobo eziqhelekileyo.Nje ukuba ugobe lokuqala lwenziwe inxalenye mhlawumbi idluliselwe komnye umatshini, okanye ukuseta okutsha kufakwe kwi-original.Ukuseta okwesibini yibha yokucaba elula.I-bend ifakwe phantsi kwe-bar flattening kwaye ivaliwe.Olu cwangciso alufuni naziphi na izixhobo ezikhethekileyo kwaye lunokukhethwa kwiindlela ezimfutshane, iiprototypes okanye iivenkile zemisebenzi eziya kufuneka zenze iindidi zobude be-hem.Njengeziqwenga ezizimeleyo zeBrake Press Tooling izixhobo ezibukhali kunye nebar ecaba ziguquguquka kakhulu, kwaye yongeza ixabiso ngaphandle kwe-hemming.I-draw backs kule nkqubo yimfuno ecacileyo yeeseti ezimbini ezizodwa, kwaye akukho lawulo lwe-thrust kwinkqubo yokucaba.

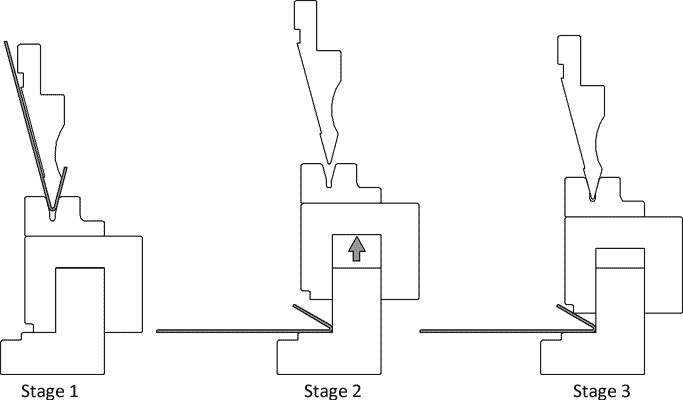

Izigaba ezimbini zeHemming Punch kunye neDie Die

Inqanaba ezibini lokufa kwe-hemming lisebenza ngokusebenzisa umjelo onzulu wokufa kunye ne-punch yekrele ebukhali.Ukugoba kokuqala kusebenzisa ijelo njenge-av yokuvula umoya ukugoba.Kwinqanaba lesibini i-punch slides kwitshaneli njengoko i-punch ivaliwe kwaye i-edge ye-punch isetyenziselwa ukubetha i-sheet metal.Ukuhlalisa i-punch ngaphakathi kwitshaneli yokufa kubuyisela amandla okuphosa kwi-die, enokuthi ikhuseleke ngokulula ngakumbi kune punch ngokwayo.I-drawback yolu hlobo lokufa kukuba lufuna ngokubonakalayo ulawulo lwe-CNC.Ngenxa yomahluko wobude phakathi kokubetha kwenqanaba lokuqala kunye nelesibini ukulungelelanisa ngesandla kuya kuthatha ixesha elininzi.Ukongeza olu hlobo lokufa lunokwahlulwa ngokulula ukusuka ngaphaya kweetoni, ukuqinisa imfuno yokhuseleko olulawulwa yikhompyutha.

Inqanaba lesithathu le-Hemming Punch kwaye Ufe

Olunye uhlobo oluqhelekileyo lwezixhobo ezenzelwe ngokukodwa ukudala i-hems linqanaba lesithathu, okanye uhlobo lwe-accordion punch kunye nokufa.I-v yokuvula ihleli phezu kwe-spring elayishiwe iphedi, ehlala phezu kwephedi ephantsi.Kwinqanaba lokuqala i-acute bend idalwe kwi-v yokuvula emva kokuba intwasahlobo ixinzelelwe kwaye i-pad ephezulu ihleli kwi-pad ephantsi.Kwinqanaba lesibini inkunzi yegusha ephezulu ihlehliswa kwaye imithombo phakathi kwepadi ephezulu nasezantsi iyibuyisela kwindawo yayo yokuqala.I sheet metal ke ibekwe phakathi iphedi eliphezulu nasezantsi kunye punch ivaliwe phantsi ukudlulisa tonnage ngokusebenzisa v die.Uncedo olukhethekileyo lunikezelwa kwi-v kufa ukuvumela esi sixhobo kwintsebenziswano yesixhobo.Isikhokelo phakathi kwephedi ephezulu kunye nesezantsi ithintela imikhosi ye-thrust ekuchaphazeleni yonke i-tooling.Idayi esezantsi ikwanika umqhubi into yokutyhala isiqwenga sokusebenza ngokuchasene nokuthintela intsimbi ukuba ingatyibiliki ngaphandle.Esi sixhobo sikhethwa kumatshini, kungekhona i-CNC, iziqhoboshi ngenxa yokuba ukwahlukana kokuphakama kwe-stroke kuncinci kakhulu, okwenza uhlengahlengiso luchithe ixesha elincinci.Oku kusekwa kukuvumela ukuba usebenzise i-punch ebukhali eqhelekileyo.

I-Tonnage iyafuneka kwi-Hemming

I-tonnage efunekayo kwi-hemming iya kuxhomekeka kumandla ezinto zakho, ubukhulu bayo kwaye okona kubaluleke kakhulu ukuba loluphi uhlobo lwe-hem ofuna ukulwenza.Ukukrazuka kweenyembezi kunye neehem ezivulekileyo azifuni phantse iitoni ezininzi njengoko umphetho osicaba.Oku kungenxa yokuba utshintsha kuphela iradiyasi yangaphakathi kancinane, ngokusisiseko uqhubeka nje ukugoba okudlule 30°.Xa uthambisa isinyithi wenza i-crease kwaye ususa i-radius yangaphakathi.Ngoku ubumba intsimbi kunokuba uyigobe.Apha ngezantsi ungabona itshathi ehemming yetoni yentsimbi eqengqelekayo.

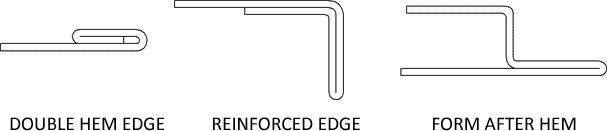

Ukusetyenziswa kwiHems

IiHems ziqhele ukusetyenziselwa ukunyanzelisa, ukufihla ukungafezeki kunye nokubonelela ngomphetho okhuselekileyo jikelele wokuphatha.Xa uyilo lufuna indawo ekhuselekileyo, kwanomphetho weendleko ezongeziweyo zemathiriyeli kunye nokusetyenzwa kwe-hem ihlala ikhethwa kwezinye iinkqubo zokunyanga komphetho.Abaqulunqi kufuneka bajonge ngaphaya komphetho omncinci omncinci wokuphatha imiphetho.Ukuphinda-phinda i-hem kunokudala i-edge ekhuseleke ngokugqibeleleyo ukuba iphathwe ngaphandle kokujonga umgangatho wokuqala womphetho.Ukongeza i-hem 'embindini' weprofayili yokugoba kunokuvula iingcango kwiiprofayili ezahlukeneyo ezingenakwenzeka ngaphandle kwe-fasteners okanye i-welding.Nangaphandle koomatshini bokuthunga abaphucukileyo, indibaniselwano yeehem ezimbini inokudala amalungu aqinileyo, aqinileyo kunye nokubopha okuncinci okanye okuncinci.Imiqukumbelo isenokusetyenziselwa ukuphinda kabini ubukhulu bentsimbi kwiindawo ezinokuthi zifune inkxaso eyongezelelweyo.Iihem ezisetyenziswa kwishishini lenkonzo yokutya kufuneka zihlale zivaliwe ngeenjongo zococeko (kunzima kakhulu ukucoca ngaphakathi kwendawo yokuvula).

Umphetho oMbindi weHem-iHem kunye nentsimbi eJinga kabini yokugobela iNkxaso-Ukusebenzisa iHem ukwenza iiProfayili eziPhezulu

Ukumisela iipateni ezisicaba zeeHem

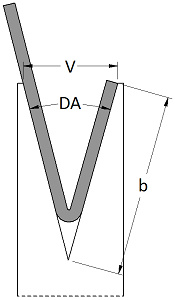

Umzekelo osicaba we-hem awubalwa ngendlela efanayo ne-bend eqhelekileyo.Oku kungenxa yokuba izinto ezifana ne-Outside Setback kunye ne-K-Factor ziba yinto engenamsebenzi njengoko i-pex ye-bend isiya kwi-infinity.Ukuzama ukubala isibonelelo somqukumbelo onje kuya kukhokelela nje kunxunguphalo.Endaweni yoko kusetyenziswa umthetho we-43% wezinto eziphathekayo xa kubalwa isibonelelo.Umzekelo ukuba izinto zethu ziyi-.0598 "kwaye sifuna ukufezekisa i-1/2" ye-hem siya kuthatha i-43% ye-.0598, .0257 kwaye songeze oko kwi-1/2 "esinika i-0.5257".Ngaloo ndlela kufuneka sishiye i-0.5257 "ekupheleni kwepateni yeflethi ukufezekisa i-1/2" ye-hem.Kufuneka kuqatshelwe ukuba lo mgaqo wesithupha awuchanekanga nge-100%.Ukuba unomdla ekudaleni umphetho ophezulu wokuchaneka kufuneka uhlale ugoba isiqwenga sesampulu, ulinganise kwaye ulungelelanise izicwangciso zakho.Kububulumko ukwenza oku kwimathiriyeli yakho eqhelekileyo kwaye wenze itshathi yokubhekisa kwixesha elizayo.Ubungakanani obuncinci okanye ubude be-hem iya b kumiselwe ngukuvulwa kwakho kwe-v yokufa kwakho.Kuya kuba bubulumko ukujonga ubude be-hem yakho emva kokugoba ngenxa yokuba inyathelo lokugqibela lokuthambisa isinyithi linokuba yinto engenakuqikelelwa ngokwendlela eyolula kwaye iflatyiswe ngayo.Ukusebenzisa ubude obusezantsi beflange kufuneka kukusondeze ngokwaneleyo kuninzi lwezicelo.Ukukhumbula iTshati ye-Air Bend Force ubuncinci ubude be-flange kwisixhobo esibukhali kukuba:

Ixesha lokuposa: Aug-27-2021