I-MAGNABEND - IINGQWELO ZOYILO EZISISEKO

Uyilo lweMazibuthe olusisiseko

Umatshini weMagnabend uyilwe njengomazibuthe weDC onamandla onomjikelo olinganiselweyo womsebenzi.

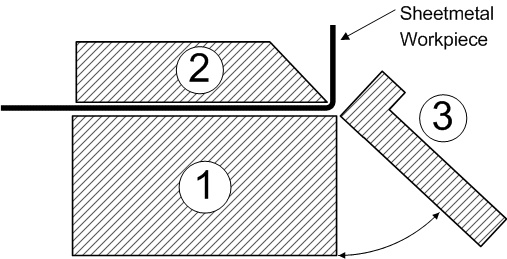

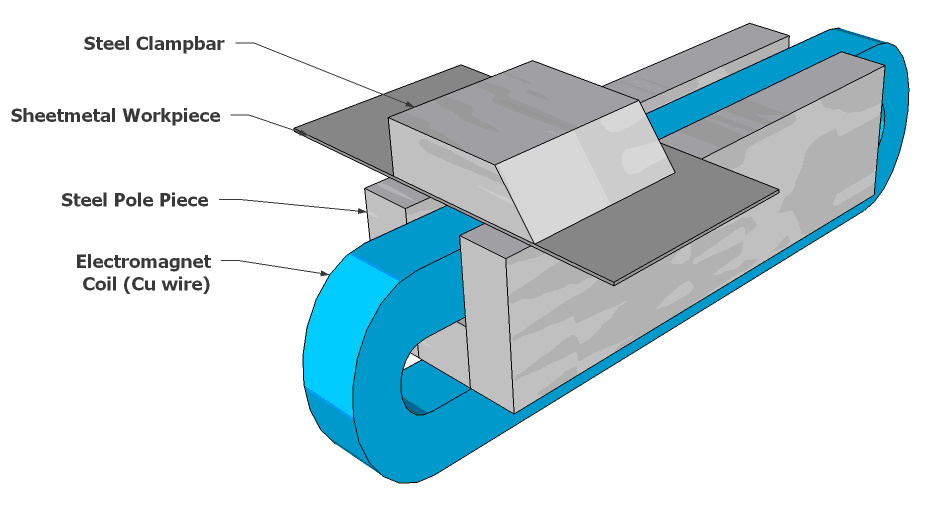

Lo matshini unamalungu ama-3 asisiseko:-

Umzimba wemagnethi owenza isiseko somatshini kwaye uqulethe ikhoyili ye-electro-magnet.

Ibha yokubambelela enika umendo wemagnethi eguquguqukayo phakathi kweepali zesiseko semagnethi, kwaye ngokwenjenjalo ibambela umsetyenzana wokusebenzela we sheetmetal.

Umqadi ogobayo ojijelwe kungqameko olungaphambili lomzimba wemagnethi kwaye ubonelela ngeendlela zokusebenzisa amandla okugoba kumsebenzi wokusebenza.

Ulungelelwaniso lweMagnet-Body

Ulungelelwaniso olwahlukeneyo lunokwenzeka kumzimba wemagnethi.

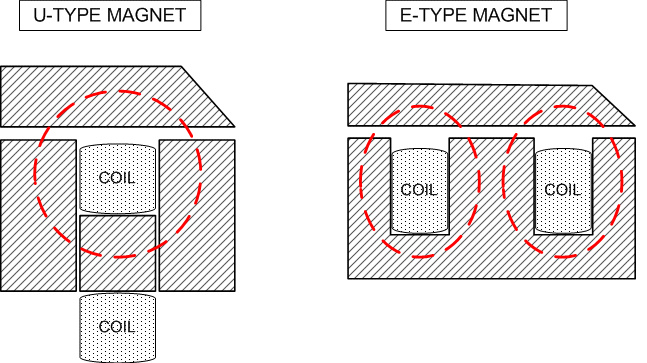

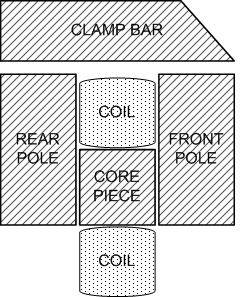

Nazi ezi-2 eziye zasetyenziswa zombini koomatshini beMagnabend:

Imigca ebomvu edayiweyo kwimizobo engentla imele iindlela zokuguquguquka kazibuthe.Qaphela ukuba uyilo lwe-"U-Type" lunomzila omnye wokuguquguquka (iipali ezi-1) ngelixa idizayini ye-"E-Type" ineendlela ezi-2 ezihambayo (izibini ezi-2 zeepali).

Uthelekiso loBumbeko lweMagnet:

Ulungelelwaniso lohlobo lwe-E lusebenza ngakumbi kunobumbeko lohlobo lwe-U.

Ukuqonda ukuba kutheni oku kunjalo qwalasela le mizobo mibini ingezantsi.

Ngasekhohlo kukho i-cross-section ye-U-type umazibuthe kwaye ekunene kukho i-E-type umazibuthe eyenziwe ngokudibanisa i-2 yohlobo olufanayo lwe-U.Ukuba uqwalaselo lwemagnethi nganye luqhutywa yicoil ene-ampere-turn efanayo, ngokucacileyo imagnethi ephindwe kabini (uhlobo lwe-E) iya kuba namandla okubamba ngokuphindwe kabini.Ikwasebenzisa intsimbi ephindwe kabini, kodwa akukho nolunye ucingo lwekhoyili!(Kucingelwa uyilo lwekhoyili ende).

(Umthamo omncinci wocingo olongezelelweyo uya kufuneka kuphela ngenxa yokuba imilenze emibini yekhoyili ihlukana ngakumbi kuyilo lwe "E", kodwa le nto yongezelelweyo iba yinto engabalulekanga kuyilo olude lwekhoyili olusetyenziselwa iMagnabend).

Super Magnabend:

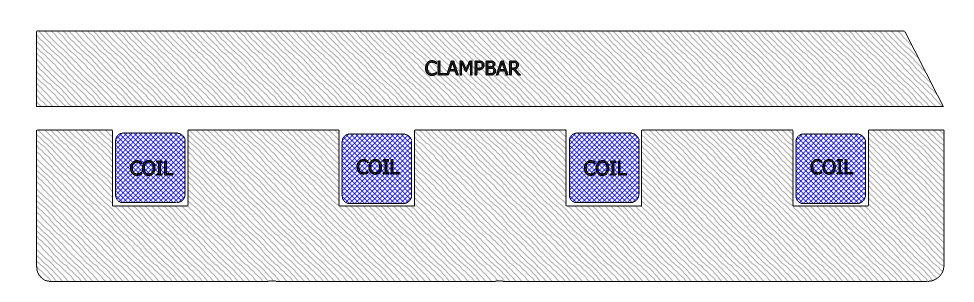

Ukwakha umazibuthe onamandla ngakumbi ingqikelelo ethi "E" inokwandiswa ngolu hlobo lwe-E kabini:

Imodeli ye-3-D:

Apha ngezantsi ngumzobo we-3-D obonisa ulungiselelo olusisiseko lwamalungu kuhlobo lwemagnethi ye-U:

Kolu luyilo iipali eziPhambili nezingasemva ziziqwenga ezahlukileyo kwaye zincanyathiselwe ngeebholiti kwiqhekeza leCore.

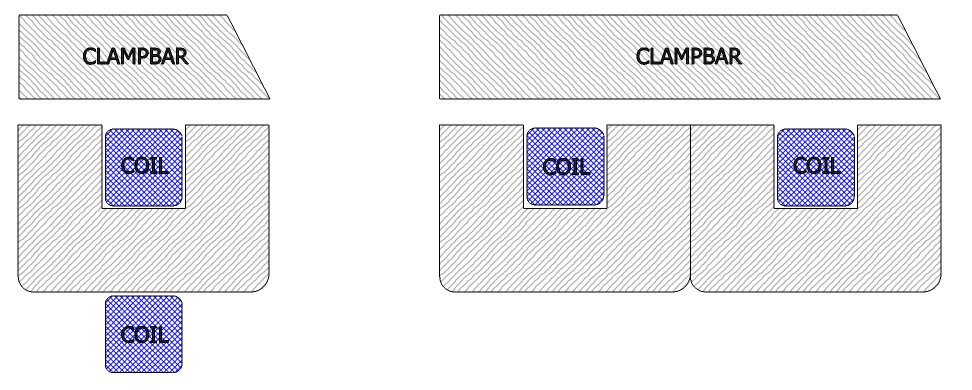

Nangona ngokomgaqo, kuya kwenzeka ukuba umatshini we-U-uhlobo lwemagnethi umzimba ukusuka kwisiqwenga esinye sentsimbi, ngekhe kube nako ukufakela ikhoyili kwaye ngoko ke ikhoyili kuya kufuneka ukuba inxebalwe kwi-situ (kumzimba wemagnethi owenziwe ngomatshini. ).

Kwimeko yokuvelisa kunqweneleka kakhulu ukukwazi ukuvuthela ii-coil ngokwahlukileyo (kwi-press special first).Ngaloo ndlela uyilo lohlobo lwe-U lumisela ngokufanelekileyo ulwakhiwo oluyiliweyo.

Kwelinye icala uyilo lohlobo lwe-E luziboleka kakuhle kumzimba ozibuthe owenziwe ngoomatshini ukusuka kwisiqwenga esinye sentsimbi kuba ikhoyili eyenziwe yangaphambili inokufakwa ngokulula emva kokuba umzimba wemagnethi wenziwe ngoomatshini.Umzimba wemagnethi onesiqwenga esinye nawo uqhuba ngcono ngokwemagnethi njengoko ungenazo naziphi na izikhewu zokwakha ezinokuthi ngenye indlela zinciphise imagnethi (kwaye ke amandla okubamba) kancinci.

(IiMagnabends ezininzi ezenziwe emva ko-1990 zisebenzise uyilo lohlobo lwe-E).

Ukukhethwa kweMathiriyeli yoLwakhiwo lweMazibuthe

Umzimba wemagnethi kunye ne-clampbar kufuneka wenziwe nge-ferromagnetic (magnetisable) imathiriyeli.Intsimbi iyeyona imathiriyeli yeferromagnetic efikelelekayo kwaye lolona khetho lucacileyo.Nangona kunjalo kukho iintlobo ezahlukeneyo zentsimbi ezifumanekayo ezinokuqwalaselwa.

1) I-Silicon Steel : Intsimbi ephezulu yokuxhathisa ehlala ifumaneka kwi-laminations encinci kwaye isetyenziswe kwi-AC transformers, i-AC magnets, i-relays njl. Iimpawu zayo azifunwa kwi-Magnabend eyi-DC magnet.

2) Intsimbi ethambileyo : Esi sixhobo siza kubonisa intsalela yemagnethi esezantsi enokuthi ilunge kumatshini weMagnabend kodwa ithambe ngokwasemzimbeni nto leyo ethetha ukuba inokubotshwa ngokulula kwaye yonakaliswe;kungcono ukusombulula ingxaki yemagnethi eshiyekileyo ngenye indlela.

3) Intsimbi yokuphosa: Ayinamagnethi ngokulula njengentsimbi eqengqelekayo kodwa inokuqwalaselwa.

4) Uhlobo lweStainless Steel 416 : Ayinakwenziwa umazibuthe njengentsimbi kwaye ibiza kakhulu (kodwa inokuba luncedo kumphezulu onqabileyo okhuselayo okhuselayo kumzimba wemagnethi).

I-5) Uhlobo lwe-Stainless Steel 316 : Le yintsimbi ye-non-magnetic alloy kwaye ayifanelekanga kwaphela (ngaphandle kwe-4 ngasentla).

6) Intsimbi yeCarbon ePhakathi, uhlobo lwe-K1045: Le nto ifaneleka ngokugqithiseleyo ukwakhiwa kwemagnethi, (kunye nezinye iindawo zomatshini).Inzima ngokwengqiqo kwimeko ebonelelweyo kwaye ikwasebenza kakuhle noomatshini.

7) Uhlobo lwe-Medium Carbon Steel CS1020 : Le ntsimbi ayinzima kakhulu njenge-K1045 kodwa ifumaneka ngokulula kwaye ngaloo ndlela inokuba lolona khetho lusebenzayo kulwakhiwo lomatshini weMagnabend.

Qaphela ukuba iipropati ezibalulekileyo ezifunekayo zezi:

High saturation magnetic.(Uninzi lweealloyi zentsimbi zigcwala malunga ne-2 Tesla),

Ukufumaneka kobukhulu becandelo eliluncedo,

Ukuchasa umonakalo onokwenzeka,

Ubuchule, kunye

Iindleko ezifanelekileyo.

Intsimbi yekhabhoni ephakathi ihambelana kakuhle nazo zonke ezi mfuno.Intsimbi yekhabhoni ephantsi nayo ingasetyenziswa kodwa ayixhathisi kangako kumonakalo owenzekayo.Kukwakho nezinye iialloyi ezikhethekileyo, ezinje nge-supermendur, ezinomagnetisa wokugcwala okuphezulu kodwa akufunekanga zithathelwe ingqalelo ngenxa yeendleko zazo eziphezulu kakhulu xa kuthelekiswa nentsimbi.

Intsimbi yekhabhoni ephakathi kodwa ibonisa intsalela yemagnethi eyaneleyo ukuba ibe yinkathazo.(Jonga icandelo kwiResidual Magnetism).

Ikhoyili

Ikhoyili yeyona nto iqhuba i-magnetising flux kwi-electromagnetic.Amandla ayo emagnethi yimveliso nje yenani lokujika (N) kunye nekhoyili yangoku (I).Ngaloo ndlela:

N = inani lokujika

Mna = ngoku kumajiko-jiko.

Ukubonakala kwe "N" kule fomyula ingentla ikhokelela kwingcamango ephosakeleyo eqhelekileyo.

Kucingelwa ngokubanzi ukuba ukonyusa inani lokujika kuya kwandisa amandla emagnethi kodwa ngokubanzi oku akwenzeki kuba ukujika okongezelelweyo nako kunciphisa langoku, I.

Qwalasela ikhoyili ebonelelwa ngombane osisigxina weDC.Ukuba inani lokujika liphindwe kabini ngoko ukuchasana kwee-windings kuya kuphinda kuphindwe kabini (kwi-coil ende) kwaye ngaloo ndlela i-current iya kuba yisiqingatha.Umphumo womnatha awukho ukwanda kwe-NI.

Eyona nto imisela i-NI kukuxhathisa ngokujika.Ngaloo ndlela ukwandisa i-NI ubukhulu bocingo kufuneka kwandiswe.Ixabiso lokujika elongezelelweyo kukuba benza ukunciphisa okwangoku kwaye ngoko ke ukuchithwa kwamandla kwikhoyili.

Umyili kufuneka akhumbule ukuba igeyiji yocingo yeyona nto igqiba amandla ombane wekhoyili.Le yeyona parameter ibaluleke kakhulu yoyilo lwekhoyili.

Imveliso ye-NI idla ngokubizwa ngokuba yi "ampere turns" yekhoyili.

Mangaphi amaJiko eAmpere afunekayo?

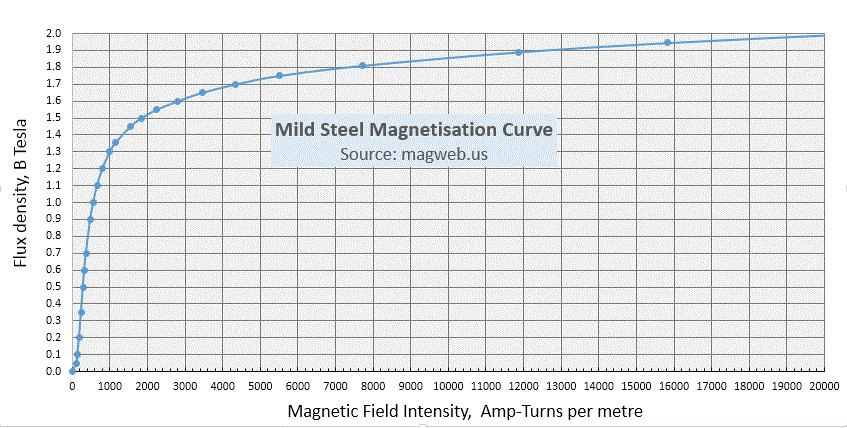

Intsimbi ibonisa i-saturation magnetisation malunga ne-2 Tesla kwaye oku kumisela umda osisiseko malunga nokuba mangaphi amandla okubamba anokufumaneka.

Ukusuka kwigrafu engentla sibona ukuba amandla entsimi afunekayo ukufumana ubuninzi be-flux ye-2 Tesla malunga ne-20,000 ampere-turns per metre.

Ngoku, kwi-design ye-Magnabend eqhelekileyo, ubude bendlela ye-flux kwintsimbi malunga ne-1/5 yemitha kwaye ngoko kuya kufuna (20,000 / 5) i-AT ukuvelisa i-saturation, malunga ne-4,000 AT.

Kuya kuba kuhle ukuba neenguqu ezininzi ze-ampere kunoko ukuze i-saturation magnetisation igcinwe naxa izikhewu ezingezizo ezemagnetic (okt ii-workpieces ezingenayo i-ferrous) zingeniswa kwisekethi yemagnethi.Nangona kunjalo ujiko olongezelelweyo lweampere lunokufunyanwa kuphela ngexabiso elikhulu lokuchitha amandla okanye ixabiso lecingo lobhedu, okanye zombini.Ngaloo ndlela ulungelelwano luyafuneka.

Uyilo oluqhelekileyo lweMagnabend lunekhoyili evelisa ukujika kwe-ampere ezingama-3,800.

Qaphela ukuba eli nani alixhomekeke kubude bomatshini.Ukuba uyilo olufana nolwemagnethi lusetyenziswa kuluhlu lobude bomatshini ngoko luyalela ukuba oomatshini abade babe nokujika okumbalwa kocingo olutyebileyo.Ziya kuzoba ngaphezulu xa zizonke zangoku kodwa ziya kuba nemveliso efanayo yee-amps x ukujika kwaye ziya kuba namandla okubamba afanayo (kunye nokuchithwa kwamandla afanayo) ngeyunithi yobude.

Isekile yomsebenzi

Ingqikelelo yomjikelo womsebenzi ngumba obaluleke kakhulu woyilo lwe-electromagnetic.Ukuba uyilo lubonelela ngomjikelo womsebenzi omninzi kunokuba ufuneka ngoko ke akulunganga.Umjikelo womsebenzi othe chatha ngokwendalo uthetha ukuba kuya kufuneka ucingo lobhedu olungaphezulu (kunye neendleko eziphezulu eziya kulandela) kunye/okanye kuya kuba mbalwa amandla okubamba akhoyo.

Qaphela: Umazibuthe womjikelo ophezulu womsebenzi uya kuba nokuchithwa kwamandla amancinci okuthetha ukuba uya kusebenzisa amandla amancinci kwaye ke kuya kuba nexabiso eliphantsi ukusebenza.Nangona kunjalo, ngenxa yokuba umazibuthe IVULIWE ixeshana nje elifutshane iindleko zamandla okusebenza zidla ngokubonwa njengongabalulekanga kakhulu.Ngaloo ndlela indlela yokuyila kukuba ube nokuchithwa kwamandla amaninzi njengoko unokuhamba malunga nokungagqithisi i-windings yekhoyili.(Le ndlela iqhelekile kuninzi lwezoyilo ze-electromagnetic).

I-Magnabend yenzelwe umjikelo oqhelekileyo womsebenzi omalunga nama-25%.

Ngokuqhelekileyo kuthatha imizuzwana emi-2 okanye emi-3 ukwenza igophe.Umazibuthe uya kuthi ke ucime imizuzwana eyi-8 ukuya kweli-10 ngelixa i-workpiece ibekwe ngokutsha kwaye ilungelelaniswe ilungele ukugoba okulandelayo.Ukuba umjikelo we-25% womsebenzi ugqithisiwe ngoko ke ekugqibeleni umazibuthe uya kushushu kakhulu kwaye ukugcwala kwe-thermal kuya kuhamba.Umazibuthe awuyi konakaliswa kodwa kuya kufuneka uvunyelwe ukuba uphole malunga nemizuzu engama-30 phambi kokuba usetyenziswe kwakhona.

Amava okusebenza ngoomatshini ebaleni abonise ukuba umjikelo we-25% ufanelekile kubasebenzisi abaqhelekileyo.Ngokwenyani abanye abasebenzisi baye bacela iinguqulelo zamandla aphezulu azikhethelayo zoomatshini ezinamandla okuqinisa ngakumbi ngeendleko zomjikelo omncinci womsebenzi.

Indawo ye-Coil Cross-Sectional

Ummandla wecandelo lomnqamlezo okhoyo kwikhoyili uya kugqiba ubuninzi bocingo lobhedu olunokuthi lufakwe kuyo.Ukubonelela indawo eninzi yekhoyili ngokuqinisekileyo kuya kwandisa ubungakanani bemagnethi kwaye kubangele ubude bendlela ye-flux kwintsimbi (eya kunciphisa i-flux epheleleyo).

Ingxabano efanayo ibonisa ukuba nayiphi na indawo yekhoyili enikezelwa kuyilo kufuneka ihlale igcwele ngocingo lobhedu.Ukuba ayigcwalanga ngoko kuthetha ukuba ijiyometri umazibuthe ibinokuba ngcono.

I-Magnabend Clamping Force:

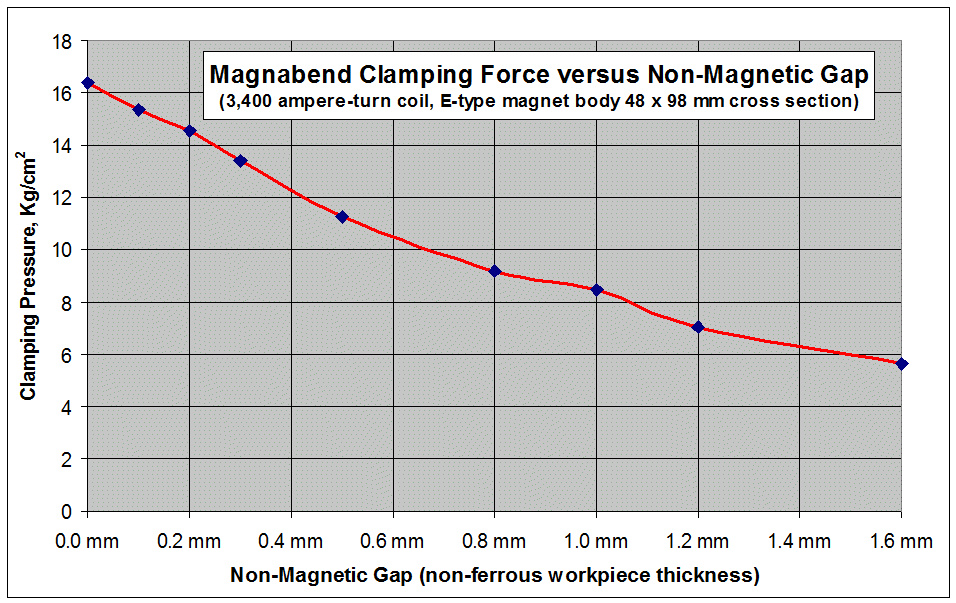

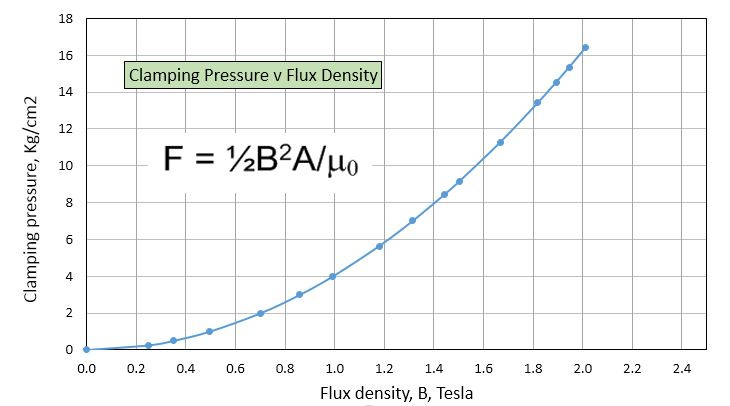

Igrafu engezantsi ifunyenwe ngemilinganiselo yovavanyo, kodwa iyavumelana kakuhle nezibalo zethiyori.

Amandla okubamba anokubalwa ngokwezibalo kule fomula:

F = amandla kwiiNewtons

B = ukuxinana kwamagnetic flux kwiTeslas

A = indawo yeepali kwi-m2

µ0 = ukungeneka kwemagnethi rhoqo, (4π x 10-7)

Umzekelo siya kubala amandla okubamba ukuxinana kwe-flux ye-2 Tesla:

Ngaloo ndlela F = ½ (2)2 A/µ0

Kumandla kwindawo yeyunithi (uxinzelelo) sinokulahla "A" kwifomula.

Ngaloo ndlela Uxinzelelo = 2/µ0 = 2/(4π x 10-7) N/m2.

Oku kuphuma kwi-1,590,000 N/m2.

Ukuguqula oku kunyanzeliso lweekhilogram kunokwahlulwa nge-g (9.81).

Ngaloo ndlela: Uxinzelelo = 162,080 kg / m2 = 16.2 kg / cm2.

Oku kuvumelana noko namandla alinganisiweyo kwisithuba esinguziro esiboniswe kule grafu ingentla.

Eli nani linokuguqulwa ngokulula libe kumandla obambeleyo opheleleyo kumatshini onikiweyo ngokuwuphindaphinda ngepali yendawo yomatshini.Kwimodeli ye-1250E indawo yesibonda yi-125 (1.4 + 3.0 + 1.5) = 735 cm2.

Ngaloo ndlela, i-zero-gap, amandla aya kuba (735 x 16.2) = 11,900 kg okanye i-11.9 tonnes;malunga ne-9.5 yeetoni ngemitha yobude bemagnethi.

Uxinzelelo lwe-Flux kunye noxinzelelo lwe-Clamping zinxulumene ngokuthe ngqo kwaye ziboniswe kwigrafu engezantsi:

Amandla okuBamba aSebenzisayo:

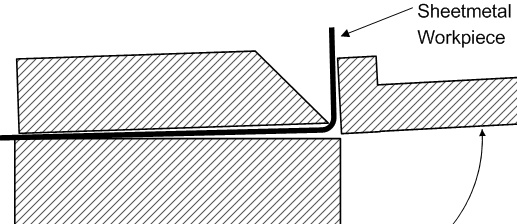

Xa usenza la mandla okubamba aphezulu abonwa kuphela xa engafunwa (!), kuxa kugoba iintsimbi zokusebenza ezibhityileyo.Xa ukugoba workpieces non-ayoni amandla aya kuba ngaphantsi njengoko kubonisiwe kwigrafu ngasentla, kwaye (kancinane ngokumangalisayo), kwakhona ngaphantsi xa ukugoba workpieces engqingqwa yentsimbi.Oku kungenxa yokuba amandla okubamba afunekayo ukwenza igophe eliphezulu kakhulu kunokufuneka kwiradius bend.Ke into eyenzekayo kukuba njengoko igophe liqhubela phambili umphetho we-clampbar uphakamisa kancinci ngaloo ndlela uvumela umsebenzi ukuba wenze iradiyasi.

Umsantsa omncinci womoya owenziweyo udala ilahleko encinci yamandla okubamba kodwa amandla afunekayo ukwenza iradiyasi egobileyo ehle kakhulu kunokuba kunamandla okubamba umazibuthe.Ngaloo ndlela imeko ezinzileyo iphumela kwaye i-clampbar ayivumeli ukuba ihambe.

Into echazwe ngasentla yindlela yokugoba xa umatshini ukufutshane nomda wobunzima.Ukuba iworkpiece engqindilili ngakumbi izanyiwe ke ngokuqinisekileyo i-clampbar iya kusuka.

Lo mzobo ucebisa ukuba ukuba umphetho wempumlo we-clampbar ubuhlaziywe kancinci, kunokuba ubukhali, ke umsantsa womoya wokugoba okungqindilili uya kuncitshiswa.

Ngenene oku kunjalo kwaye i-Magnabend eyenziwe ngokufanelekileyo iya kuba ne-clampbar ene-radiused edge.(I-radiused edge nayo ayifane yenzeke kakhulu kumonakalo owenziwe ngengozi xa kuthelekiswa nencam ebukhali).

Imowudi eseludinini yokusilela kokugobela:

Ukuba ukugoba kuzanywa kwisixhobo sokusebenza esishinyene kakhulu ngoko umatshini uya kusilela ukugoba kuba i-clampbar iya kusuka ngokulula.(Ngethamsanqa oku akwenzeki ngendlela ekhwankqisayo; i-clampbar iyeke ihambe izolile).

Nangona kunjalo ukuba umthwalo ogobayo mkhulu kancinane kunomthamo wokugoba wemagnethi ngoko ngokubanzi into eyenzekayo kukuba igophe liya kuqhubeka lithetha malunga needigri ezingama-60 kwaye ke iclampbar iya kuqala ukutyibilika ngasemva.Kule ndlela yokusilela umazibuthe unokuxhathisa umthwalo ogobayo ngokungathanga ngqo ngokudala ingxabano phakathi kwendawo yokusebenza kunye nebhedi yemagnethi.

Umahluko wobunzima phakathi kokusilela ngenxa yokunyuswa kunye nokusilela ngenxa yokutyibilika awukho kakhulu.

Ukungaphumeleli kokuphakanyiswa kubangelwa yi-workpiece ehambisa umda wangaphambili we-clampbar ukuya phezulu.Amandla okubamba kumphetho ongaphambili we-clampbar yeyona nto ixhathisayo oku.Ukubambelela kumda ongasemva kunesiphumo esincinci kuba ikufuphi nalapho i-clampbar iphiwuthelwa khona.Enyanisweni sisiqingatha kuphela samandla okubamba apheleleyo amelana nokunyuswa.

Kwelinye icala, ukutyibilika kuchaswa ngamandla abambeneyo ewonke kodwa ngokukhuhlana kuphela ngoko ke ukona kokwenyani kuxhomekeke kumlinganiso wokukhuhlana phakathi kwesixhobo sokusebenza kunye nomphezulu wemagnethi.

Kwintsimbi ecocekileyo neyomileyo i-friction coefficient ingaba phezulu njenge-0.8 kodwa ukuba i-lubrication ikhona ngoko inokuba ngaphantsi kwe-0.2.Ngokwesiqhelo iya kuba kwindawo ethile phakathi kangangokuba indlela esecaleni yokusilela ukugoba idla ngokuba ngenxa yokutyibilika, kodwa iinzame zokunyusa ukukhuhlana kumphezulu wemagnethi zifunyenwe zingafanelekanga.

Ukutyeba Umthamo:

Kumzimba wemagnethi wohlobo lwe-E oyi-98mm ububanzi kunye ne-48mm ubunzulu kunye ne-3,800 ampere-turn coil, ubude obugcweleyo bokugoba yi-1.6mm.Obu bunzima busebenza kuzo zombini ishidi lentsimbi kunye nephepha le-aluminium.Kuya kubakho ukucinezela okuncinci kwiphepha le-aluminium kodwa kufuna i-torque encinci ukuyigoba ukuze oku kuhlawulele ngendlela yokunika amandla afanayo okulinganisa kuzo zombini iindidi zentsimbi.

Kufuneka kubekho izilumkiso kumthamo ochaziweyo wokugoba: Eyona nto iphambili kukuba amandla esivuno seshiti lesinyithi anokwahluka kakhulu.Umthamo we-1.6mm usebenza kwintsimbi kunye noxinzelelo lwesivuno ukuya kwi-250 MPa kunye ne-aluminium kunye noxinzelelo lwesivuno ukuya kwi-140 MPa.

Umthamo wobunzima kwintsimbi engenasici malunga ne-1.0mm.Lo mthamo ungaphantsi kakhulu kunezinye iintsimbi ezininzi ngenxa yokuba intsimbi engatyiwa iqhelekile ayiyo-magnetic kodwa inoxinzelelo lwesivuno oluphezulu.

Enye into bubushushu bemagnethi.Ukuba umazibuthe uvunyelwe ukuba shushu ke ukuxhathisa kwekhoyili kuya kuba phezulu kwaye oku kuya kubangela ukuba itsale kancinci ngoku kunye nesiphumo esisezantsi se-ampere-turns kunye ne-clamping force ephantsi.(Esi siphumo sikholisa ukuba phakathi kwaye akunakwenzeka ukuba kubangele ukuba umatshini ungafezekisi imimiselo yawo).

Okokugqibela, umthamo omkhulu weMagnabends unokwenziwa ukuba icandelo lomnqamlezo wemagnethi lenziwe likhulu.