Ukulandela izicelo ezininzi ngoku ndongeza imizobo eneenkcukacha ye-Magnabend centerless hinges kule webhusayithi.

Nceda uqaphele nangona kunjalo ukuba ezi hinges zinzima kakhulu ukwenza umatshini omnye.

Iinxalenye eziphambili zehinge zifuna ukuphosa ngokuchanekileyo (umzekelo ngenkqubo yotyalo-mali) okanye ukulungiswa ngeendlela ze-NC.

Abathandi bokuzonwabisa akufuneki bazame ukwenza le hinge.

Nangona kunjalo abavelisi banokuyifumana le mizobo iluncedo kakhulu.

(Ukuze kube lula ukwenza ihenjisi i-HEMI-HINGE esandul' ukuphuhliswa iyacetyiswa. Bona inkcazo epheleleyo kunye nemizobo apha).

IMagnabend CENTRELESS COMPOUND HINGE yaqanjwa nguMnumzana Geoff Fenton kwaye yayinelungelo elilodwa lomenzi kumazwe amaninzi.(Amalungelo awodwa abenzi ngoku aphelelwe lixesha).

Uyilo lwezi hinge luvumela umatshini weMagnabend ukuba uvuleke ngokupheleleyo.

Umqadi ogobayo ujikeleza i-axis ebonakalayo, ehlala ingaphezulu kancinane kumphezulu womsebenzi womatshini, kwaye umqadi unokujinga ngokujikeleza iidigri ezili-180 ezipheleleyo.

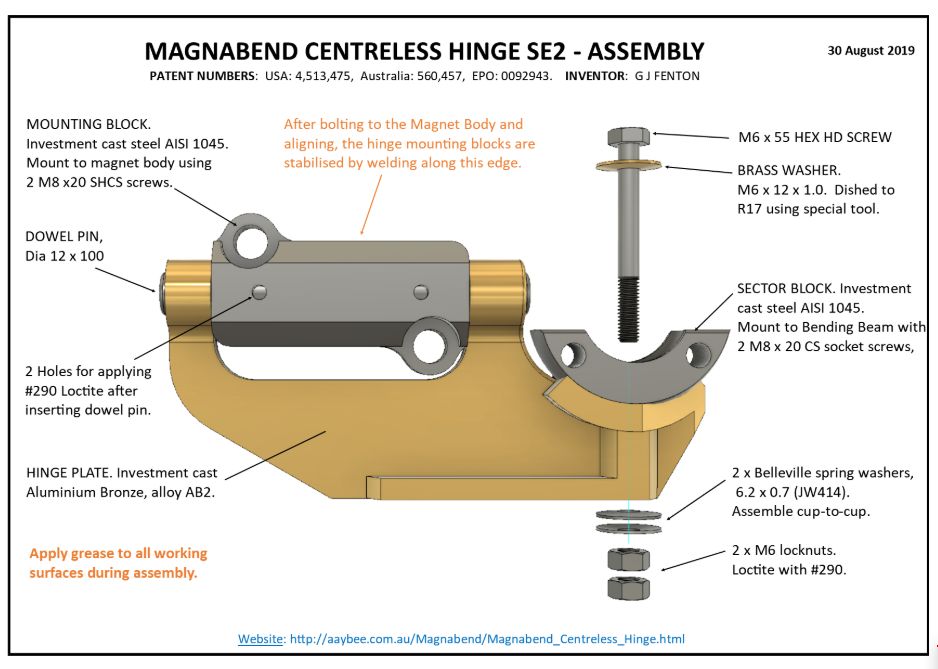

Kwimizobo kunye nemifanekiso engezantsi kuphela indibano enye yeehinge iboniswa.Nangona kunjalo, ukuze uchaze i-hinge axis, kufuneka kufakwe ii-asemblies ezi-2 ubuncinane.

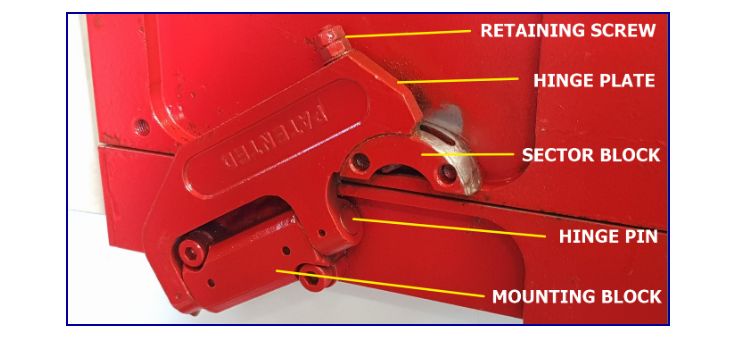

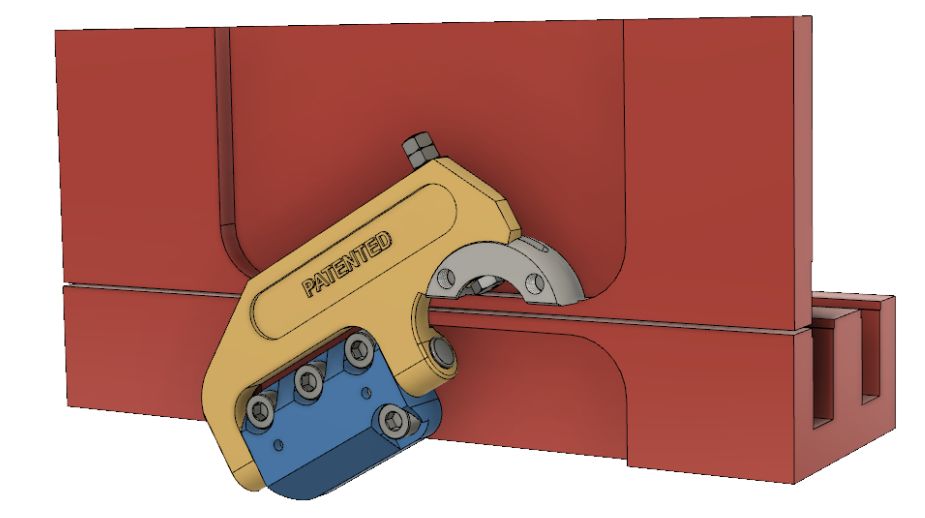

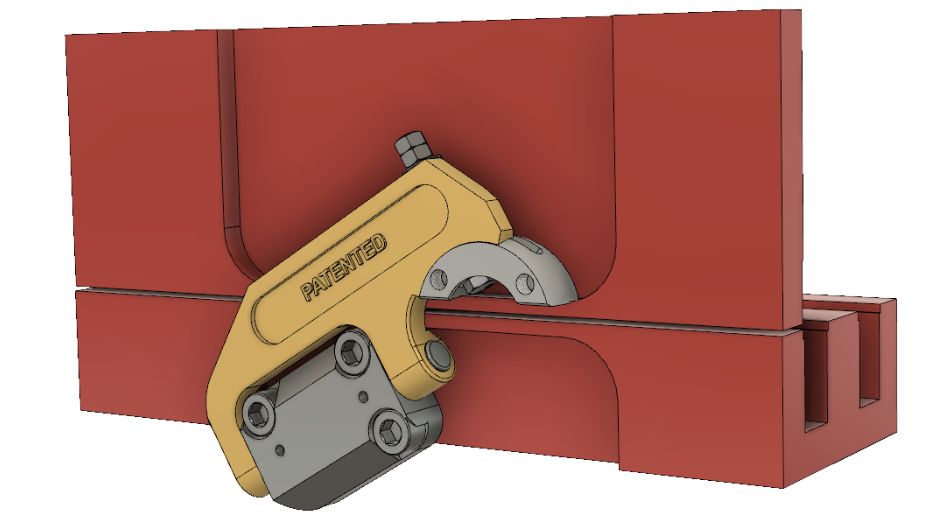

INdibano yeeHinge kunye neCandelo lokuchongwa (i-bending beam kwii-180 degrees):

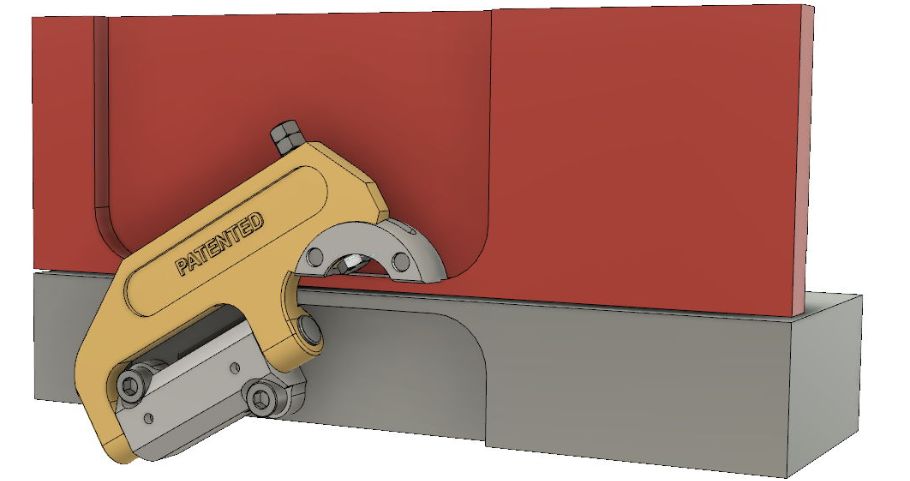

Ihinge eneBeam yokuGobela malunga nenqanaba le-90 kwindawo:

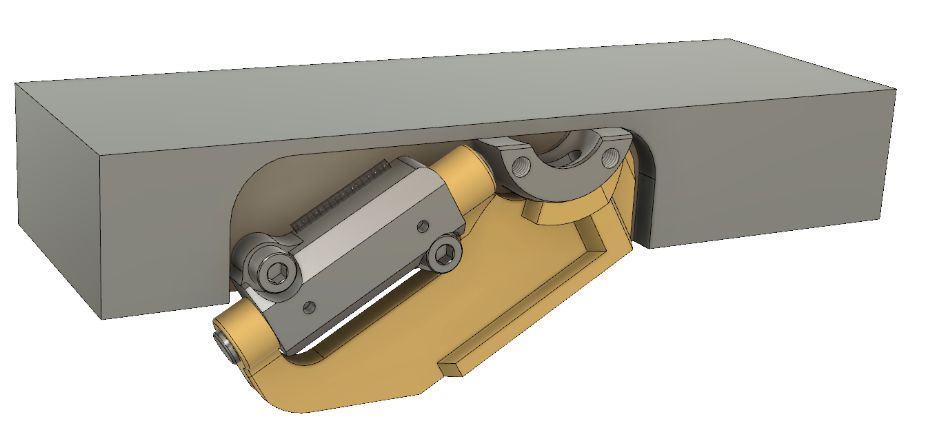

INdibano yeeHinge ezinyusiweyo-3DModels:

Umzobo ongezantsi uthathwe kwimodeli ye-3-D yehinge.

Ngokucofa le fayile ilandelayo "ISINYATHELO": IMounted Hinge Model.step uya kuba nakho ukubona imodeli ye-3D.

(Ezi Apps zilandelayo ziya kuvula .iifayile zenyathelo: AutoCAD, Solidworks, Fusion360, IronCAD okanye "kwimboniselo" yezo apps).

Ngemodeli ye-3D evuliweyo ungajonga amalungu kuyo nayiphi na i-engile, sondeza ukubona iinkcukacha, okanye wenze amanye amalungu anyamalale ukuze ukwazi ukubona amanye amalungu ngokucacileyo.Unokwenza imilinganiselo kuwo nawaphi na amalungu.

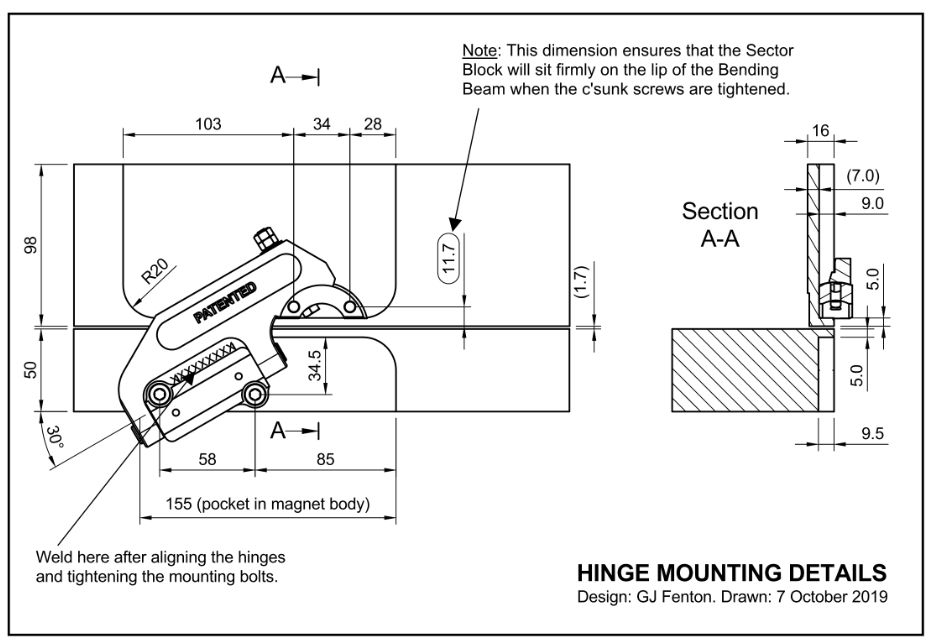

Imilinganiselo yokunyuswa kweNdibano yeeHinge:

Indibano yeHinge:

Cofa kumzobo ukubona owandisiweyo.Cofa apha ukuze ufumane ifayile ye-pdf: I-Hinge Assembly.PDF

Imizobo eneenkcukacha:

Iifayile zemodeli ye-3D (iifayile ze-STEP) ezibandakanyiweyo apha ngezantsi zinokusetyenziselwa ukuprinta kwe-3D okanye kwiComputer Aid Manufacturing (CAM).

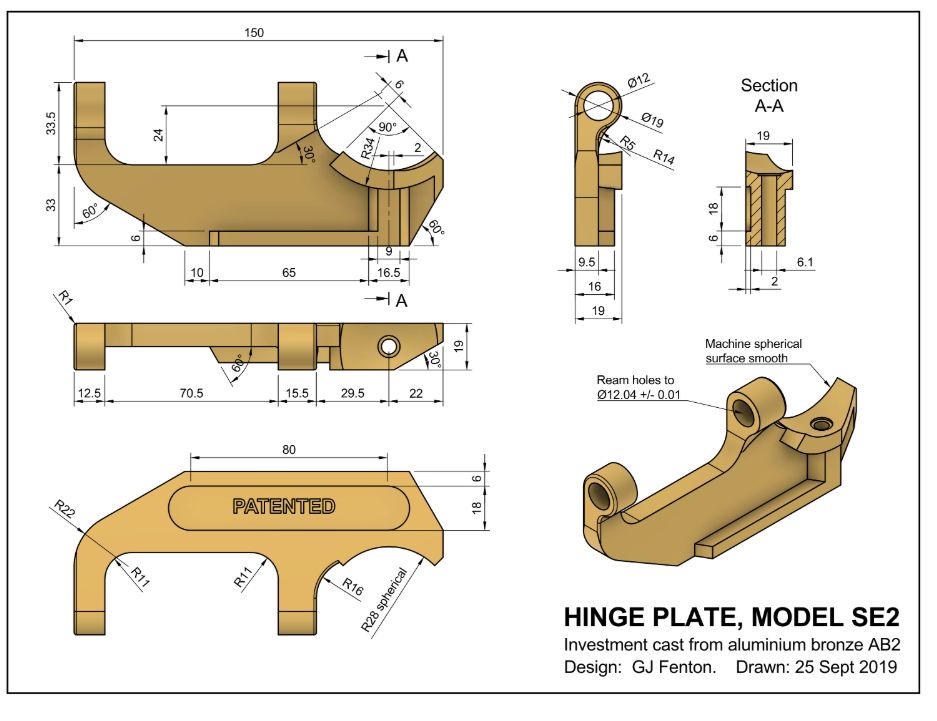

1. Ipleyiti yehinge:

Cofa kumzobo ukubona owandisiweyo.Cofa apha ukuze ufumane ifayile ye-pdf: I-Hinge Plate.PDF.Imodeli ye-3D: I-Hinge Plate.step

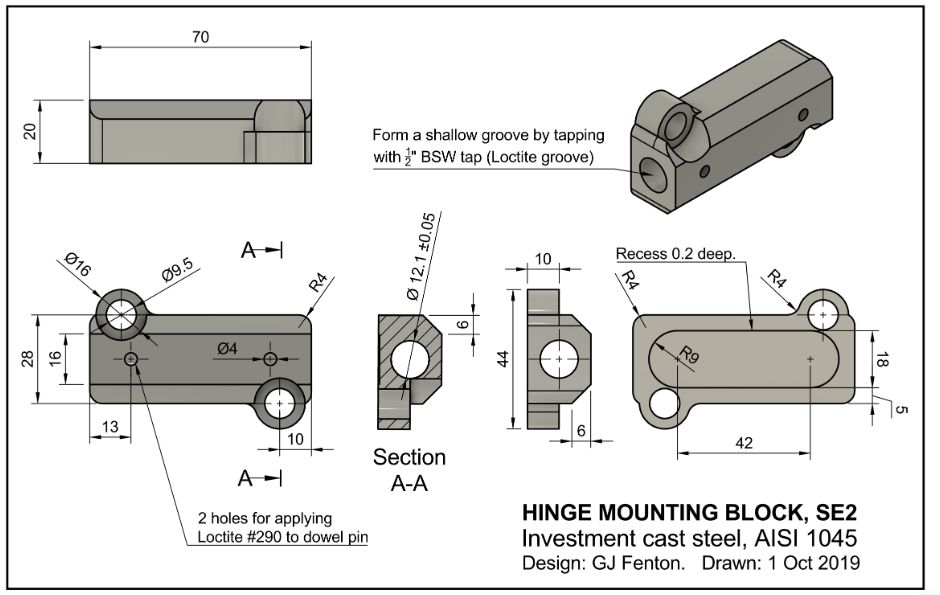

2. Ibhloko yokuNqamisa:

Cofa kumzobo ukuze ukwandise.Cofa apha ukuze ufumane ifayile yepdf: Mounting_Block-welded.PDF, 3D Model: MountingBlock.step

Isixhobo seBhlokhi yokuMounting yi-AISI-1045.Le ntsimbi yekhabhoni iphezulu ikhethwa ngenxa yokomelela kwayo okuphezulu kunye nokuxhathisa ukujikeleza kumngxuma we-hinge pin.

Nceda uqaphele ukuba le block yehinge yokuxhoma yenzelwe ukuzinziswa ngokufakwa kumzimba wemagnethi emva kolungelelwaniso lokugqibela .

Qaphela kwakhona iinkcukacha zomsonto ongekho nzulu ngaphakathi komngxuma wephini lokuhombisa.Lo msonto ubonelela ngomjelo we-wick-in Loctite esetyenziswa ngexesha lokuhlanganisana kweehinge.(Izikhonkwane zehinge zinento eyomeleleyo yokusebenza ngaphandle kokuba zitshixelwe kakuhle).

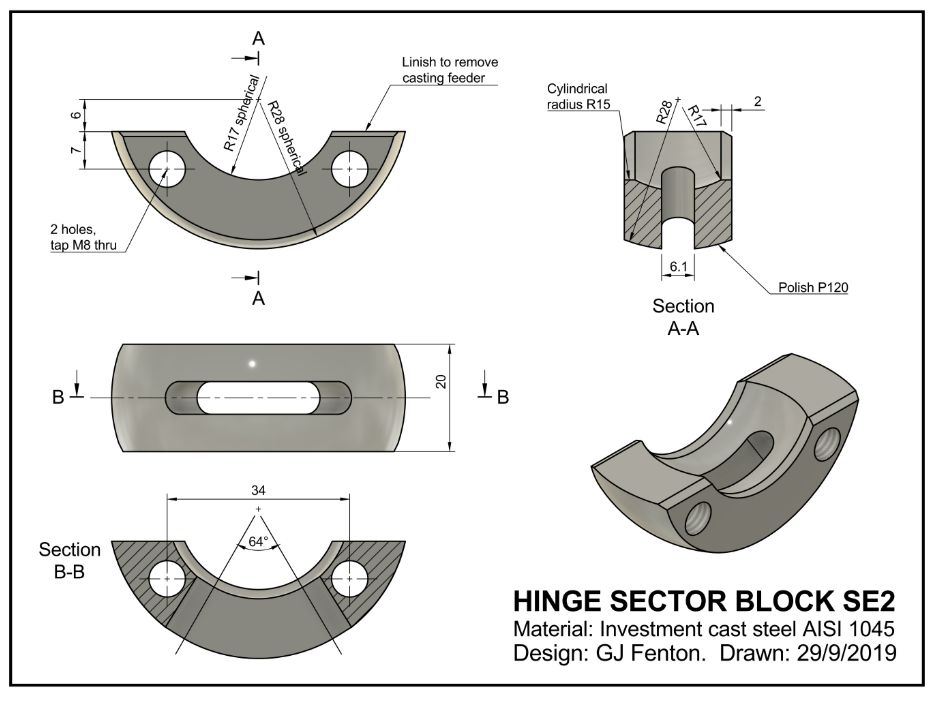

3. Ibhloko yeCandelo:

Cofa kumzobo ukubona owandisiweyo.Cofa apha kwifayile ye-pdf: I-Sector Block.PDF, ifayile ye-3D yeCad: i-SectorBlock.step

4. I-Hinge Pin:

Isikhonkwane sentsimbi esiqinileyo kunye nomhlaba ochanekileyo.

IHINGES EBOLDED-ON

Kwimizobo kunye neemodeli ezingentla kwendibano yehenjisi ibholitiwe kwiBeam yokugoba (ngezikrufu kwiBhloko yeCandelo) kodwa uncamathiselo kwiMagnet Body luxhomekeke kwibholiti KUNYE ne welding.

Indibano yehinge iya kuba lula ngakumbi ukwenziwa kunye nokuyifaka ukuba i-welding ayifunwa.

Ngexesha lophuhliso lwehinge siye safumanisa ukuba asikwazi ukufumana ukukhuhlane okwaneleyo ngeebholiti zodwa ukuqinisekisa ukuba ibhloko exhomayo ayiyi kutyibilika xa kusetyenziswa imithwalo ephezulu yendawo.

Qaphela:Amanqina eebholiti ngokwawo awakuthinteli ukutyibilika kweBloko yokuFaka ngenxa yokuba iibholithi zikwimingxuma emikhulu.Ukucocwa kwimingxuma kuyimfuneko ukubonelela ukulungiswa kunye nokungachaneki okuncinci kwizikhundla.

Nangona kunjalo siye sanikezela ngeehenjisi ezitshiswe ngokupheleleyo kuluhlu loomatshini abakhethekileyo beMagnabend ababeyilelwe imigca yemveliso.

Kwabo matshini imithwalo yehenjisi yayiphakathi kwaye yayichazwe kakuhle kwaye ke iihenjisi eziboshiweyo zazisebenza kakuhle.

Kumzobo ongezantsi kweBloko yokuHlanga (umbala obhulowu) uyilelwe ukuba wamkele iibholithi ezine ze-M8 (kunokuba zimbini iibholithi ze-M8 kunye nokuwelda).

Olu yayiluyilo olusetyenziselwa umgca wemveliso weMagnabend oomatshini.

(Senza malunga nama-400 abo matshini bakhethekileyo abanobude obahlukahlukeneyo ubukhulu becala ebudeni beminyaka yee-1990).

Nceda uqaphele ukuba iibholithi ezimbini eziphezulu ze-M8 zingena kwipali yangaphambili yemagnethi yomzimba obunzima obuyi-7.5mm kuphela kwindawo ephantsi kwepokotho yehinge.

Ngoko ke ezi zikrufu akufunekanga zidlule kwi-16mm ubude (9mm kwibhloko yokuxhoma kunye ne-7mm kumzimba wemagnethi).

Ukuba izikrufu bezisekude ngoko beziya kuphazamisana nekhoyili yeMagnabend kwaye ukuba bezimfutshane kukho ubude bemisonto obungonelanga, okuthetha ukuba imisonto ibinokuhluba xa izikrufu zijikijelwa kuxinzelelo lwazo olucetyiswayo (39 Nm).

Ibhloko yokuNyikisa iiBolt ze-M10:

Senze uvavanyo oluthile apho imingxuma yebhloko exhomayo yandisiwe ukuze yamkele iibholiti ze-M10.Ezi bholiti zikhulu zinokukhutshelwa kwi-tension ephezulu (77 Nm) kwaye oku, kudityaniswe nokusebenzisa i-Loctite #680 phantsi kwebhloko yokunyusela, kubangele ukukhuhlana okungaphezulu kokwaneleyo ukuthintela ukutyibilika kwebhloko yokuxhoma kumatshini oqhelekileyo weMagnabend (olinganiswe ukugoba. ukuya kuthi ga kwintsimbi ye-1.6mm).

Nangona kunjalo olu yilo lufuna ukulungiswa kunye novavanyo olungakumbi.

Lo mzobo ungezantsi ubonisa ihenjisi efakwe kumzimba wemagnethi ngeebholithi ezi-3 x M10:

Ukuba nawuphi na umenzi angathanda iinkcukacha ezithe kratya malunga nehinge ebote ngokupheleleyo nceda uqhagamshelane nam.

Ixesha lokuposa: Oct-12-2022