Uyilo lweMazibuthe olusisiseko

Umatshini weMagnabend uyilwe njengomazibuthe weDC onamandla onomjikelo olinganiselweyo womsebenzi.

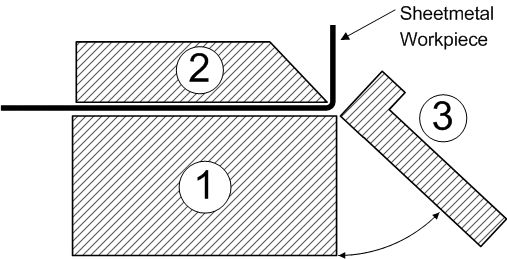

Lo matshini unamalungu ama-3 asisiseko:-

Umzimba wemagnethi owenza isiseko somatshini kwaye uqulethe ikhoyili ye-electro-magnet.

Ibha yokubambelela enika umendo wokuguquguquka kwemagnethi phakathi kweepali zesiseko semagnethi, kwaye ngokwenjenjalo ibambela icwecwe lecwecwe.

Umqadi ogobayo ojijelwe kungqameko olungaphambili lomzimba wemagnethi kwaye ubonelela ngeendlela zokusebenzisa amandla okugoba kwisixhobo sokusebenza.

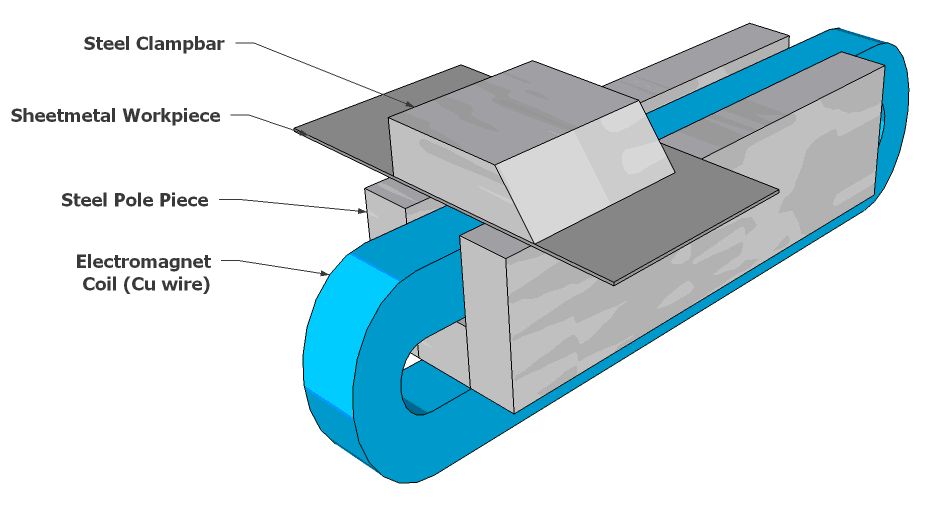

Imodeli ye-3-D:

Apha ngezantsi ngumzobo we-3-D obonisa ulungiselelo olusisiseko lwamalungu kuhlobo lwemagnethi ye-U:

Isekile yomsebenzi

Ingqikelelo yomjikelo womsebenzi ngumba obaluleke kakhulu woyilo lwe-electromagnetic.Ukuba uyilo lubonelela ngomjikelo womsebenzi omninzi kunokuba ufuneka ngoko ke akulunganga.Umjikelo womsebenzi othe chatha ngokwendalo uthetha ukuba kuya kufuneka ucingo lobhedu olungaphezulu (ngesiphumo seendleko eziphezulu) kunye/okanye kuya kubakho amandla amancinci okubamba akhoyo.

Qaphela: Umazibuthe womjikelo ophezulu womsebenzi uya kuba nokuchithwa kwamandla amancinci okuthetha ukuba uya kusebenzisa amandla amancinci kwaye ke kuya kuba nexabiso eliphantsi ukusebenza.Nangona kunjalo, ngenxa yokuba umazibuthe IVULIWE ixeshana nje elifutshane iindleko zamandla okusebenza zidla ngokubonwa njengongabalulekanga kakhulu.Ngaloo ndlela indlela yoyilo kukuba ube nokuchithwa kwamandla amaninzi njengoko unokuhamba malunga nokungagqithisi i-windings yekhoyili.(Le ndlela ixhaphakile kuninzi loyilo lwe-electromagnetic).

I-Magnabend yenzelwe umjikelo oqhelekileyo womsebenzi omalunga nama-25%.

Ngokuqhelekileyo kuthatha imizuzwana emi-2 okanye emi-3 ukwenza igophe.Umazibuthe uya kuthi ke ucime imizuzwana eyi-8 ukuya kweli-10 ngelixa i-workpiece ibekwe ngokutsha kwaye ilungelelaniswe ilungele ukugoba okulandelayo.Ukuba umjikelo we-25% womsebenzi ugqithisiwe ngoko ke ekugqibeleni umazibuthe uya kushushu kakhulu kwaye ukugcwala kwe-thermal kuya kuhamba.Umazibuthe awuyi konakaliswa kodwa kuya kufuneka uvunyelwe ukuba uphole malunga nemizuzu engama-30 phambi kokuba usetyenziswe kwakhona.

Amava okusebenza ngoomatshini ebaleni abonise ukuba umjikelo we-25% ufanelekile kubasebenzisi abaqhelekileyo.Ngokwenyani abanye abasebenzisi baye bacela iinguqulelo zamandla aphezulu azikhethelayo zoomatshini ezinamandla okuqinisa ngakumbi ngeendleko zomjikelo omncinci womsebenzi.

I-Magnabend Clamping Force:

Amandla okuBamba aSebenzisayo:

Ngokwenza la mandla okubamba aphezulu abonwa kuphela xa engafuneki (!), kuxa kugoba izinto zokusebenza zentsimbi.Xa kugotywa ii-workpieces ezingezizo i-ferrous amandla aya kuba ngaphantsi njengoko kubonisiwe kwigrafu engentla, kwaye (kancinci ngokumangalisayo), kuncinci xa kugoba i-workpieces yentsimbi eshinyeneyo.Oku kungenxa yokuba amandla okubamba afunekayo ukwenza igophe eliphezulu kakhulu kunokufuneka kwiradiyasi egobileyo.Ke into eyenzekayo kukuba njengoko igophe liqhubela phambili umphetho we-clampbar uphakamisa kancinci ngaloo ndlela uvumela umsebenzi ukuba wenze iradiyasi.

Umsantsa omncinci womoya owenziweyo udala ilahleko kancinane yamandla okubamba kodwa amandla afunekayo ukwenza iradiyasi egobileyo ehle kakhulu kunokuba kunamandla okubamba umazibuthe.Ngaloo ndlela imeko ezinzileyo iphumela kwaye i-clampbar ayivumeli ukuba ihambe.

Into echazwe ngasentla yindlela yokugoba xa umatshini ukufutshane nomda wawo wobunzima.Ukuba iworkpiece engqindilili ngakumbi izanyiwe ke ngokuqinisekileyo i-clampbar iya kusuka.

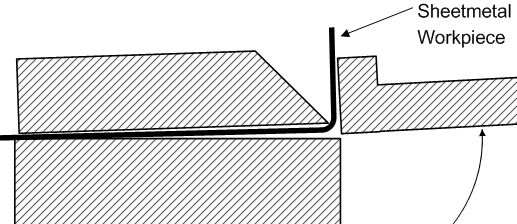

Lo mzobo ucebisa ukuba ukuba umphetho wempumlo we-clampbar ubuhlaziywe kancinci, kunokuba ubukhali, ke isithuba somoya sokugoba okungqindilili siya kuncitshiswa.

Ngenene oku kunjalo kwaye i-Magnabend eyenziwe ngokufanelekileyo iya kuba ne-clampbar ene-radiused edge.(I-radiused edge nayo ayifane yenzeke kakhulu ekonakalisweni ngengozi xa kuthelekiswa nencam ebukhali).

Imowudi eseludinini yokusilela kokugobela:

Ukuba ukugoba kuzanywa kwisixhobo sokusebenza esishinyene kakhulu emva koko umatshini uya kusilela ukugoba kuba i-clampbar iya kusuka ngokulula.(Ngethamsanqa oku akwenzeki ngendlela ekhwankqisayo; i-clampbar iyeke ihambe izolile).

Nangona kunjalo ukuba umthwalo ogobayo mkhulu kancinane kunomthamo wokugoba wemagnethi ke ngokubanzi into eyenzekayo kukuba igophe liya kuqhubeka lithetha malunga needigri ezingama-60 kwaye ke iclampbar iya kuqala ukutyibilika ngasemva.Kule ndlela yokusilela umazibuthe unokuxhathisa umthwalo ogobayo ngokungathanga ngqo ngokudala ingxabano phakathi kwendawo yokusebenza kunye nebhedi yemagnethi.

Umahluko wobunzima phakathi kokusilela ngenxa yokunyuswa kunye nokusilela ngenxa yokutyibilika awukho kakhulu.

Ukungaphumeleli kokuphakanyiswa kubangelwa yi-workpiece ehambisa umda wangaphambili we-clampbar ukuya phezulu.Amandla okubamba kumphetho ongaphambili we-clampbar yeyona nto imelana noku.Ukubambelela kumda ongasemva kunesiphumo esincinci kuba ikufuphi nalapho i-clampbar iphiwuthelwa khona.Enyanisweni sisiqingatha kuphela samandla okubamba apheleleyo amelana nokunyuswa.

Kwelinye icala, ukutyibilika kuchaswa ngamandla abambeneyo ewonke kodwa ngokukhuhlana kuphela ngoko ke ukona kokwenyani kuxhomekeke kumlinganiso wokukhuhlana phakathi kwesixhobo sokusebenza kunye nomphezulu wemagnethi.

Kwintsimbi ecocekileyo neyomileyo i-friction coefficient ingaba phezulu njenge-0.8 kodwa ukuba i-lubrication ikhona ngoko inokuba ngaphantsi kwe-0.2.Ngokwesiqhelo iya kuba kwindawo ethile phakathi kangangokuba indlela esecaleni yokusilela ukugoba idla ngokuba ngenxa yokutyibilika, kodwa iinzame zokunyusa ukukhuhlana kumphezulu wemagnethi zifunyenwe zingafanelekanga.

Ukutyeba Umthamo:

Kumzimba wemagnethi wohlobo lwe-E oyi-98mm ububanzi kunye ne-48mm ubunzulu kunye ne-3,800 ampere-turn coil, ubude obugcweleyo bokugoba yi-1.6mm.Obu bunzima busebenza kuzo zombini ishidi lentsimbi kunye nephepha le-aluminium.Kuya kubakho ukuqina okuncinci kwiphepha le-aluminiyam kodwa kufuna i-torque encinci ukuyigoba ukuze oku kuhlawulelwe ngendlela yokunika amandla afanayo okulinganisa kuzo zombini iindidi zentsimbi.

Kufuneka kubekho izilumkiso kumthamo ochaziweyo wokugoba: Eyona nto iphambili kukuba amandla esivuno seshiti lesinyithi anokwahluka kakhulu.Umthamo we-1.6mm usebenza kwintsimbi kunye noxinzelelo lwesivuno ukuya kwi-250 MPa kunye ne-aluminium kunye noxinzelelo lwesivuno ukuya kwi-140 MPa.

Umthamo wobunzima kwintsimbi engenasici malunga ne-1.0mm.Lo mthamo ungaphantsi kakhulu kunezinye iintsimbi ezininzi ngenxa yokuba intsimbi engatyiwayo ihlala ingenamagnetic kodwa inoxinzelelo lwesivuno oluphezulu.

Enye into bubushushu bemagnethi.Ukuba umazibuthe uvunyelwe ukuba shushu ke ukuxhathisa kwekhoyili kuya kuba phezulu kwaye oku kuya kubangela ukuba itsale kancinci ngoku kunye nesiphumo esisezantsi se-ampere-turn kunye ne-clamping force ephantsi.(Esi siphumo sikholisa ukuba phakathi kwaye akunakwenzeka ukuba kubangele ukuba umatshini ungahlangabezani neenkcukacha zawo).

Okokugqibela, umthamo omkhulu weMagnabends unokwenziwa ukuba icandelo lomnqamlezo wemagnethi lenziwe likhulu.

Ixesha lokuposa: Aug-12-2022